Hydrogen From Sunlight

Gas producer, Air Products (AP), recently unveiled a solar-powered hydrogen fueling station. Their SmartFuel® technology uses electrolysis to make hydrogen from water, so providing fuel

Gas producer, Air Products (AP), recently unveiled a solar-powered hydrogen fueling station. Their SmartFuel® technology uses electrolysis to make hydrogen from water, so providing fuel

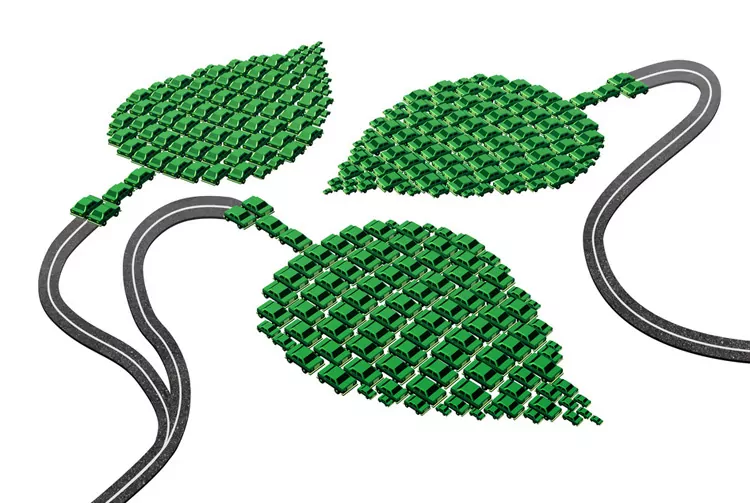

Fuel cells, which produce electricity by combining hydrogen and oxygen, offer a tantalizing glimpse of an oil-free future. An alternative to carrying heavy batteries, a

Every year more and more people voluntarily expose themselves to intense laser light. Lasers surround us at work and home, but they can be dangerous,

Mosquito Misting Systems Summer is here, and with the long days and rising temperatures come the mosquitos. The top months for mosquito presence are June,

When residents of a New York City neighborhood saw a tree disappearing down a hole in the summer of 2012, it was obvious something was

Your company’s reputation depends on how your products perform in-service, and their performance depends on choosing the right material for each component. Use PVC when

Now that the hole in the ozone layer is starting to heal, (according to a UNEP press release,) this intriguing molecule has dropped out of

LCA Series: Custom piston and LED light Installation: Vertical Industry: Residential or Commercial Media: Gas

Natural gas is a domestically produced fossil fuel comprised mostly of methane. It is one of the cleanest burning alternatives to gasoline, diesel and propane

Despite all the low energy lightbulbs and high efficiency appliances, demand for electricity is projected to increase over the next 25 years. More air conditioners

We’ve all been through an automatic car wash at some point in our lives. We sit patiently inside the car while it sprays soap, scrubs,

In the power generation industry, it’s essential to maintain the chemistry of steam and water within prescribed limits to prevent performance-eroding corrosion and catastrophic failure,

Pumps come in many shapes and sizes and have endless applications in manufacturing, energy, food processing and mineral mining. High flow pumps can take on

The National Fire Protection Association (NFPA) is the world’s leading advocate of fire prevention and an authoritative source on public safety. The NFPA develops, publishes

Taking paper waste to an offsite shredding facility can be inconvenient and expensive. Mobile paper shredding trucks offer a way to insure the security of important