Pumps come in many shapes and sizes and have endless applications in manufacturing, energy, food processing and mineral mining. High flow pumps can take on some of the world’s toughest jobs. For example, barrel pumps transport crude oil at 700 degrees Celsius, centrifugal pumps can build islands and beaches and larger centrifugal pumps can move fluids at 200,000 gallons per minute. ChemTec’s specialty is in low flow valves and monitors, and for pumps, this means applications in sampling, hydraulic and cooling systems, applications we might encounter every day.

Pumps in Cooling Systems

An application that is probably more familiar is the cooling system in a car’s engine. A cooling system is made of parts and fluid that work together to control an engine’s operating temperature for optimal performance while the thermostat is the valve that measures the temperature of the coolant and opens to allow hot fluid to travel to the radiator. If the thermostat becomes stuck and quits working, it will affect the entire cooling system.

Pumps can have two types of flow: constant or pulsing. ChemTec specializes in flow valves and monitors that could be used in numerous types of pumps and handle both kinds of flow. We’re proud to say our flow meters and monitors can handle pulsing and constant flows in pumps and won’t fail or shut down because of other variables.

ChemTec Featured Products

MAO Series

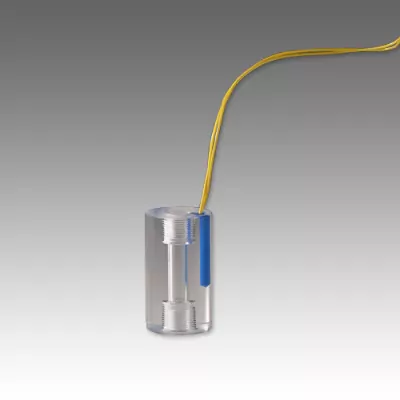

ChemTec’s MAO Series flow meter is a reliable, accurate, economical low flow meter with a microprocessor-based conditioning circuit capable of sending a signal to computer controlled and remote controlled process equipment. The MAO Series handles all liquids & aggressive chemicals, offers all Teflon wetted parts, and is available in three sizes.

LPH Series

Additionally, the LPH Series is a non-adjustable liquid/gas flow monitor that is capable of monitoring flows of corrosive and non-corrosive liquids andgases. The LPH is available in Acrylic, Brass, 316SS or Teflon and can be used for applications like laser cooling systems, bubbler systems and pollution sampling equipment.

Related Industry Articles

Reducing Pulsation in Peristaltic Pumping Systems

As fluid enters the head of a peristaltic pump, it becomes trapped between two rollers. This “pillow” of fluid is followed by a void, where the tubing is occluded by the rollers. Alternating pillows and voids cause fluid flow to be pulsated, rather than smooth and continuous. READ MORE.

How is Globalization Affecting the Pump Industry?

Globalization, or the integration of countries including their cultures and trade practices, has brought together an array of industries including telecommunications, transportation, energy, and more. Now the process has stretched into the pump industry due to the worldwide demand for the applications in which pumps are used, such as clean water and energy. READ MORE.