Now that the hole in the ozone layer is starting to heal, (according to a UNEP press release,) this intriguing molecule has dropped out of the headlines. It’s a pity because ozone’s ability to protect us goes beyond blocking solar ultraviolet radiation.

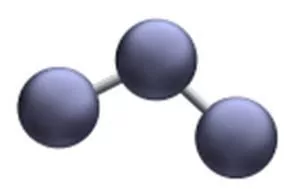

Ozone (O3) is the three-atom form of oxygen. Whereas the two-atom form is found in the air we breathe,

Ozone Applications

Ozone’s ability to disinfect has created two areas of application: water purification and medicine. For over a century cities have used ozone to clean their drinking water. This avoids the need for chlorine or other hazardous chemicals, and as an added benefit, because ozone decays to oxygen there are no disposal issues.

Medical uses of ozone date from the First World War where it was found effective in treating infections. Today it’s used to treat burns and slow-to-heal wounds by pumping a low concentration into a bag encasing the affected region. Ozone is also used in dentistry where it’s dissolved in water, and many other applications are being researched.

Making Ozone

Ozone is produced by exposing oxygen to either very high voltages, (as happens during a lightning strike,) or to ultraviolet (UV) light. Most clinical ozone generators use the high voltage method. Here, either ambient air or pure oxygen is first filtered and dried, then passed through a corona-discharge device. High voltages turn some of the oxygen to ozone which is piped to the patient.

Handling Ozone

The properties that make ozone a powerful disinfectant also create challenges. It is toxic in anything above low concentrations, so should not be allowed to escape into the treatment area. For this reason most ozone generators incorporate an ozone destructor.

Ozone also reacts with many materials, especially rubbers and plastics such as nylon. This means when designing clinical ozone generators care must be given to material selection.

ChemTec Featured Product – 500 BP Series

In devices like clinical ozone generators a flow monitor provides assurance of

Related Industry Articles

A Clinical Review of Ozone Therapy

Medical uses of ozone continue to be debated and researched. In 2011 the National Institute of Health (NIH) published a review of work in this area, concluding that, “Ozone therapy … effects are proven, consistent, safe and with minimal and preventable side effects.” (READ MORE)

Ultra-High Purity Case Study

Medical device manufacturers and the pharmaceutical and semiconductor industries depend on exceptionally pure fluids and contamination can be very expensive. The Ultra Pure 500 BP flow monitor delivers the in-service performance demanded by these users. (READ MORE)