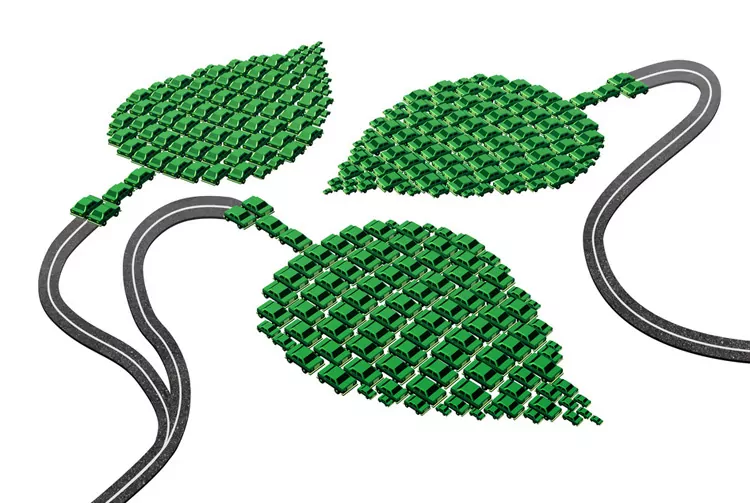

Fuel cells, which produce electricity by combining hydrogen and oxygen, offer a tantalizing glimpse of an oil-free future. An alternative to carrying heavy batteries, a fuel cell-powered car needs only a supply of hydrogen to generate all the energy it needs.

Some manufacturers have fuel cell cars on the road already, but three factors are holding back wider adoption:

- Lack of infrastructure for distributing hydrogen to refueling stations.

- Cost and complexity of producing hydrogen gas. Typically it comes from natural gas, but can also be produced by electrolysis – using electricity to break down water. Both sources result in CO2 emissions.

- Concerns over safety.

“Green” Gas from Biomass

These problems would be largely overcome if it was possible to make hydrogen in small quantities at the place where it’s needed, like at a gas station. If the production process was environmentally friendly, even better! Scientists at Virginia Tech recently reported that this might be possible.

Their approach is to take biomass, or more specifically, corn ‘stover’, (the cobs, husks and stalks left over from harvesting and processing,) and release hydrogen gas through controlled decomposition. There’s more work to be done, but the concept certainly appears feasible and the team has funding to develop a demonstrator.

This would overcome the problem of needing large scale hydrogen production facilities plus distribution and storage. Instead, stover processing units could be set up at rural gas stations and run on locally grown corn. Distribution problems would be eliminated, and carbon emissions per unit of hydrogen would be lower, enhancing its appeal as an environmentally friendly fuel.

Addressing the Safety Concern

There is however an elephant lurking in this attractively ‘green’ room: hydrogen is highly flammable. Worse still, it burns with an almost invisible flame, so a single spark could turn a small leak into an inferno without anyone noticing. Clearly, safety systems will be essential components of these local biomass-to-hydrogen operations, to both eliminate ignition sources and detect leaks.

Leak detection is something ChemTec can help with. An Excess Flow Valve, or EFV, prevents uncontrolled flows of liquids or gases. Should a pipe or hose become disconnected or a leak develop, an EFV senses the resulting change in flow and closes off the line. The technology is already widely used in CNG installations, so it’s no stretch to imagine it finding a home in small biomass hydrogen production stations.

Ready for the Future

Powering vehicles with fuel cells is an appealing prospect. The only by-product is water, and the need for heavy batteries goes away. All that’s needed is an efficient way to make the hydrogen and deliver it to our vehicles. If the Virginia Tech scientists are successful that problem will soon be solved by small-scale local production. When that day arrives, ChemTec will be ready with EFVs to keep those facilities safe.