ChemTec is an engineering-driven company, and engineering is really about applying the Laws of Physics. We’re familiar with analyzing gas flow rates, accounting for expansion coefficients, and monitoring the position of suspended magnetic pistons, but optical engineering is outside of our realm. Or it was until a customer set us a challenge we couldn’t resist.

The Challenge

This particular customer uses our LPH flow monitors in a range of small-scale bench-top processing equipment. The LPH series of monitors are designed for low flow liquid and gas applications, sending a signal whenever the flow goes over or drops below preset limits. These work by suspending a magnetic piston in the flow. Changes in flow rate cause a displacement in piston position that gets sensed by a reed switch. This way equipment can be protected from any damage that would result from a partial blockage or similar problem.

The customer’s equipment employs both air and water, running through pipes with ‘push to connect’ fittings. Part of normal operation required users to disconnect and reconnect the air and water lines, and as these look alike it was possible for a user to make the wrong pipe connections. Should a mistake be made and the lines incorrectly connected, water would flow through air lines and vice-versa. The consequences could be rather expensive.

Facing this problem, the customer asked Chemtec for a sensor that could detect the presence of water in the lines. In addition, it had to operate very quickly, and be small enough to fit into the existing design.

The Solution

The LPH monitors that the customer already used measure fluid flow but cannot tell what fluid is flowing. Distinguishing water from air was an unusual request and ChemTec had nothing in the catalog that would do the job. Other companies might just have said, “Sorry, we can’t help,” but that’s not the way ChemTec engineers like to work.

Intrigued, our R&D group set about researching a solution, and optics turned out to be the key. When light passes from one medium to another the change in optical density bends the light path in a phenomenon known as refraction. In extreme cases the angle of incidence combined with difference between two media can make the light reflect back off the surface rather than passing through. Termed “total internal reflection,” this is the principle behind fiber-optics lighting.

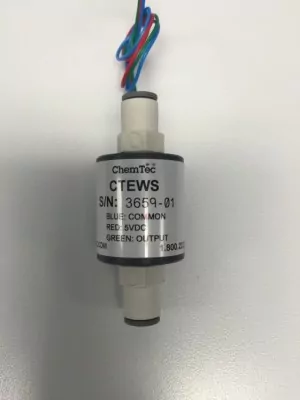

Air and water have different refractive indices. By carefully shining light from an LED at the appropriate angle it’s possible to configure a sensor that reflects when there’s no liquid present, yet transmits and refracts when in water. With a small photo-detector positioned to catch the reflected light, the sensor works as an electrical switch. It’s an ingenious answer to a tricky problem.

Unique Capabilities

Few companies have both the resources and the willingness to undertake this kind of product development effort. The engineers at ChemTec enjoy technical challenges, but what really differentiates the company is that manufacturing and R&D are both undertaken within the US. This gives the R&D team access to the full range of production resources – materials, tools, machines, and most importantly, people – and it lets them design for ease of manufacture.

When a company has complete control over design, development and manufacturing it can respond quickly to customer requests like this one. Perhaps more importantly, it can develop customized solutions to unique challenges, solving problems for customers and helping them deliver superior products.

Responsive

Engineers are natural problem-solvers, but at ChemTec we believe our R&D team are exceptional in the way they rise to customer challenges. A water sensor was not to be found in our product catalog, but when the customer asked we responded, showing once again the value of US-based manufacturing combined with talented R&D engineers.