Reverse osmosis (RO) is a widely utilized process that affects many aspects of our daily lives. For example, RO helps food manufacturers concentrate fruit juice, aquarium operators maintain their tanks, and cities and campers produce drinking water from something dirty or salty. It’s difficult to make it through a day without using a product created with reverse osmosis.

How reverse osmosis works

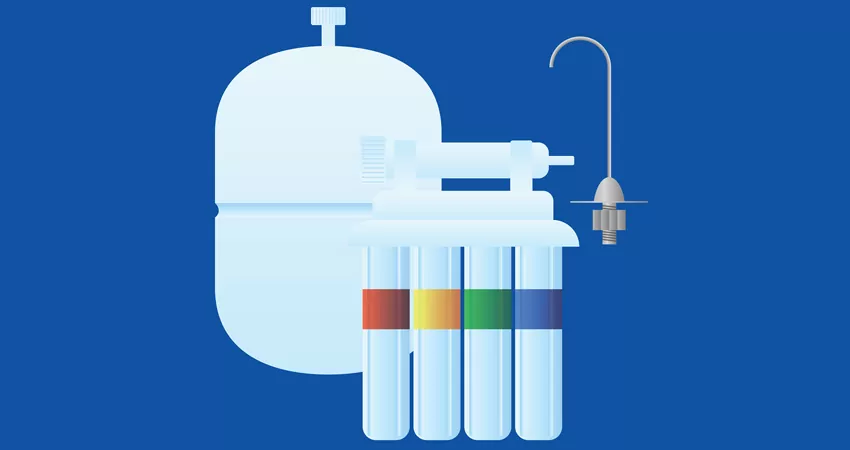

A reverse osmosis system by definition works by pressurizing water and forcing it through a semipermeable membrane to remove ions, molecules, and larger particles from the water. You can click here to find more details about the process. However, a typical reverse osmosis system is much more complicated than that and can have a series of filters, shut-off valves, and flow restrictors to make an efficient system. Restricting the flow of water is especially important, and monitoring that is vital to the success of an RO system.

How ChemTec’s LCA Series improves reverse osmosis

A flow monitor alerts operators quickly if flow rates are outside normal limits, letting them take appropriate corrective action. In this case, ChemTec’s LCA flow monitor is a great addition to reverse osmosis systems. It can be installed to protect pumps, monitor flow, signal flow/noflow conditions for quality, and monitor operating pressures. Knowing that different clients and industries have unique reverse osmosis systems, ChemTec directly with them to create customized solutions that deliver maximum efficiency.