Gas escaping from pipework needs to be detected quickly. Depending on the type of gas, the consequences range from merely wasteful to fatal. Leaking gas can be environmentally damaging and pose an explosion risk.

ChemTec offers a range of products designed to help detect these leaks quickly and effectively, including flow monitors that provide real-time detection of abnormal conditions.

Introducing Flow Monitors for Gas Leak Detection

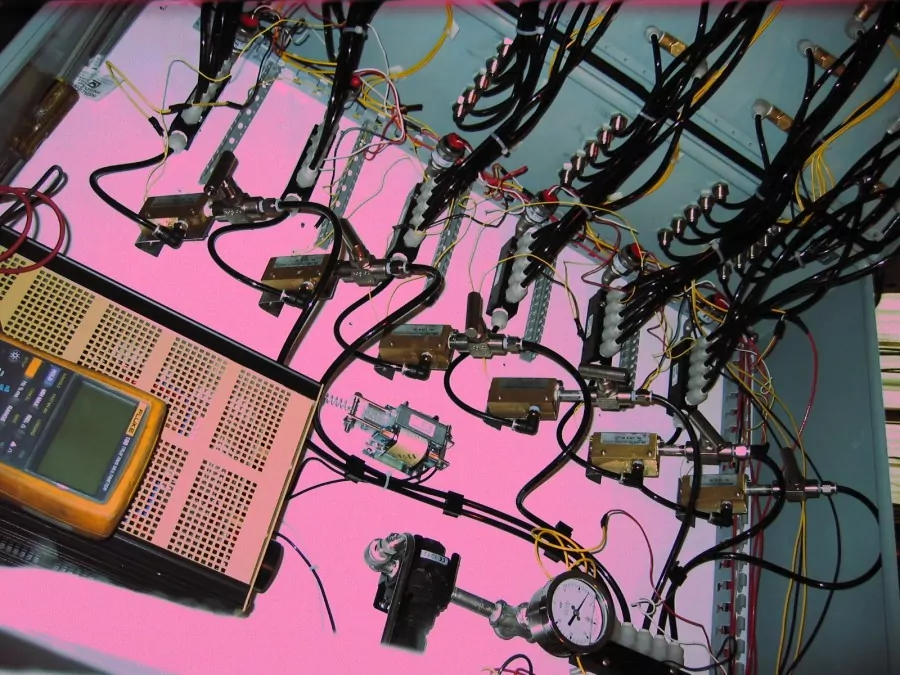

Gas sensors can detect the presence of gas, but flow monitors provide an alternative approach by identifying leaks as they occur. ChemTec’s 125 Series Flow Monitor uses a magnetic piston system to detect changes in gas flow, triggering an alarm when abnormal conditions arise.

These monitors also sense blockages and surges, offering real-time detection to enhance system safety and efficiency. Watch this video to see how flow monitors can improve leak detection and provide a reliable solution for maintaining safe operations.

Ensure System Safety with ChemTec Flow Monitors and Sensors

Gas leaks are a serious problem. Technologies exist to sense the presence of gas in the air, but it’s also possible to detect when a leak is happening. Ultrasonic sensors will ‘hear’ the high-frequency whistle of escaping gas, and flow monitors can send an alarm whenever an abnormal condition occurs.

Call us if you have any questions about the 125 series flow monitors for gas leak detection.