Flow monitors are a crucial component of any manufacturing operation. But with so many to choose from, how can you ensure you’re getting a flow monitor that’s well-suited to your specific applications? Learn more about the mechanics of flow measurement and how ChemTec’s products can make it easy to select the perfect flow monitor for your purposes.

How Flow Monitors Work

Flow monitors are designed to measure the amount of gas or liquid passing through them. Some flow monitors provide per-minute measurements, while others measure the total amount of gas or fluid that has passed through them.

Flow monitors can be broken down into several categories by type:

- Volumetric flow monitors directly measure fluid volume passing through the monitor.

- Velocity flow monitors measure the volumetric flow by tracking the velocity of the stream.

- Mass flow monitors measure the mass flow of the stream.

- Inferential flow monitors don’t rely on volume, velocity, or mass, but instead, infer flow measure through other parameters.

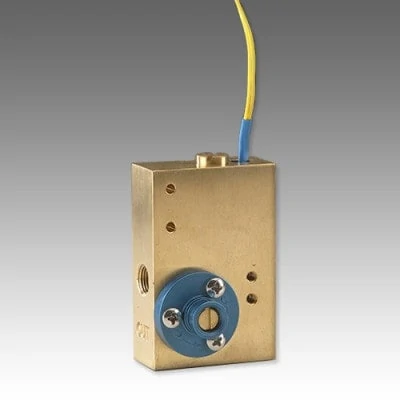

Some flow monitors, like volumetric monitors, work best with fluid applications. Others are primarily geared toward measuring the velocity of gases. ChemTec’s 125 bypass (BP) series of flow monitors do double duty and are designed to fit many liquid and gas applications.

Choosing the Right Flow Monitor

When it comes to choosing a flow monitor, there’s no one “right” choice for every situation. The ideal flow monitor will depend on the application, needs, and desired metrics. A flow monitor that can be perfect to direct the stream of oxygen needed for tig welding may not work as well for a PC cooling system. To choose the right flow monitor, consider some of the following factors.

Accuracy

Sometimes, it’s absolutely crucial for a flow monitor to deliver 100 percent accuracy, 100 percent of the time. In other cases, a bit of variance won’t have much of an impact on the final application. By determining how important accuracy is for your application, you’ll be able to weigh this among other factors and decide which flow monitor best fits the bill.

Cost

The price range of your ideal flow monitor will again depend on the specifics of your application. In many cases, a low-cost flow monitor may check off all your boxes; in other situations, particularly where your needs require a custom flow monitor, it may be worthwhile to invest in a pricier version.

Durability

When assessing durability, you’ll want to consider not only the cost of replacing a flow monitor, but also the opportunity cost of having your operations down until a flow monitor can be replaced.

By keeping these factors in mind while browsing flow monitors, you’ll be well on your way to choosing the ideal one for your purposes. ChemTec can help. Visit our website to learn more about our 125 bypass (BP) series of flow monitors and the other products we offer.