Contact Protection Requirements

When switching inductive loads such as relays, solenoids and transformers, reed switch contacts require protection in order to insure long dependable life. When current is interrupted, the inductance or electrical inertia of the load generates a large high frequency voltage, which spreads across the switch contacts. If the voltage is large enough, it can break down the medium in the gap between them, making a conductive path. This phenomenon, called “arcing” is the spark you see. Arcing can cause the contacts to burn, weld together or stick; thus, giving unreliable performance.

The purpose of protection circuits is to prevent arcing, by shortening this voltage through an alternate path.

Recommended Protection – D.C.

A 1N4004 diode (or equivalent) connected cathode-to-positive is recommended. The diode does not conduct when the load is energized, but conducts and shorts out the generated voltage when the switch opens. The generated voltage always acts in series with the applied voltage.

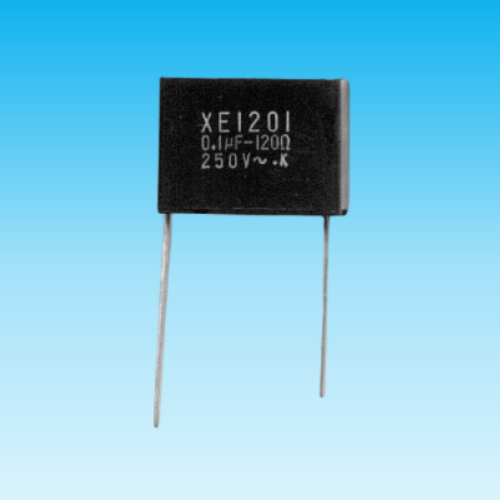

Recommended Protection – A.C.

A resistor and capacitor connected in parallel with the switch is recommended. The capacitor is a high impedance to 60 hertz, but is essentially a short circuit to high frequencies of generated voltages.

Transient suppressors or varistors may also be used to dissipate the transient and protect the switch contacts.