Metal casting and plastic molding are near-net shape manufacturing processes. Liquid material fills a die, solidifies and is ejected. A few quick finishing operations later and a precision part is ready for shipping or assembly. The key to making money though is doing this quickly. Molding and casting machines are expensive, as are the dies, so throughput and utilization must be maximized. That means chilling the filled die as fast as possible, and that takes sophisticated cooling systems.

Cooling Options

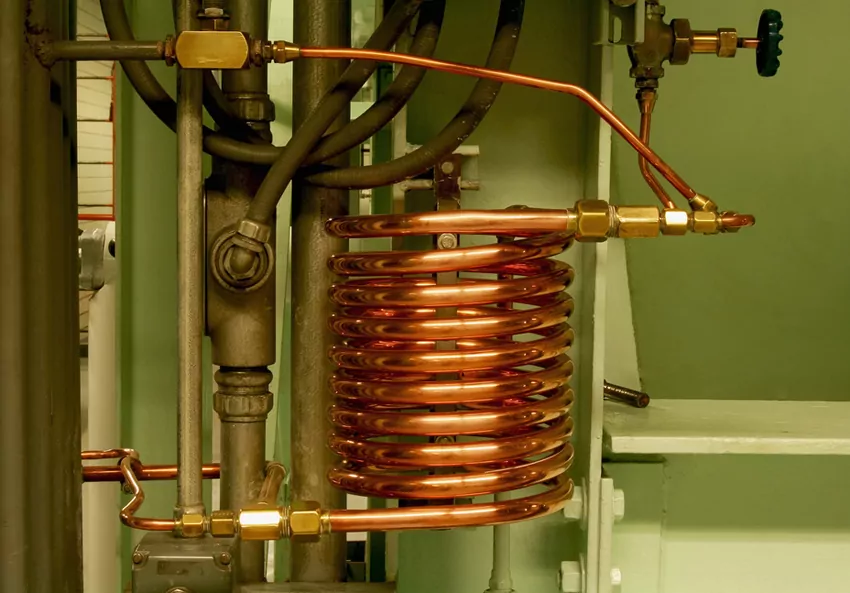

Most cooling is achieved by running cold water through the hot production tooling. Heat is transferred into the water and the metal or plastic solidifies. In the past manufacturers might have run the warm water straight into a drain, but today that’s recognized as wasteful and potentially environmentally harmful. (It does however have the advantage that tap water is usually at a consistent temperature.) Three superior alternatives are:

- Cooling tower. Using the principle of cooling by evaporation, pipes carrying water from the process run into a tower. Cold water sprays over these pipes and a proportion evaporates, taking the heat with it. Cooling tower systems are often found in large-scale operations as well as power generation. As water is lost running costs are quite high. Additionally, scale can build up in pipes, reducing heat trasnfer efficiency.

- Water chiller. Effectively a mini-refrigerator, these run the process water through chilled coils. They are effective in small scale cooling situations but have very high running costs.

- Adiabatic cooling. Like the cooling tower, this method uses cooling by evaporation, but in a closed-loop system. Hot water from the process heats air that is in turn drawn through water-moistened pads. This moisture evaporates, lowering the temperature of the air. The water is subsequently recovered and reused. As a result, water consumption and electricity usage are both very low. Click here for more details.

The ChemTec Contribution

Monitors like the LPH series sense abnormal flow conditions with a magnetic piston suspended in the fluid stream. If the flow moves outside of set limits the magnetic field changes by a small but detectable amount. When this happens an alarm can be set or other actions taken as appropriate, such as shutting down fan motors.

Flow Matters

Cooling is essential to keep the cost of casting and molding processes low, and also in other applications like data centers. Most of these systems use water to take heat away from the source, followed by some form of exchanger to cool the water. Any reduction in flow upsets the efficiency of the system, perhaps forcing a shutdown for repairs. Flow monitors provide early notification of changes of flow before they become serious and expensive.

If you’re interested in learning how a ChemTec flow monitor could improve the efficiency and reliability of your process or equipment, contact us today.